Fire-Resistant Ship Interiors for Safety at Sea

What is Marine Outfitting?

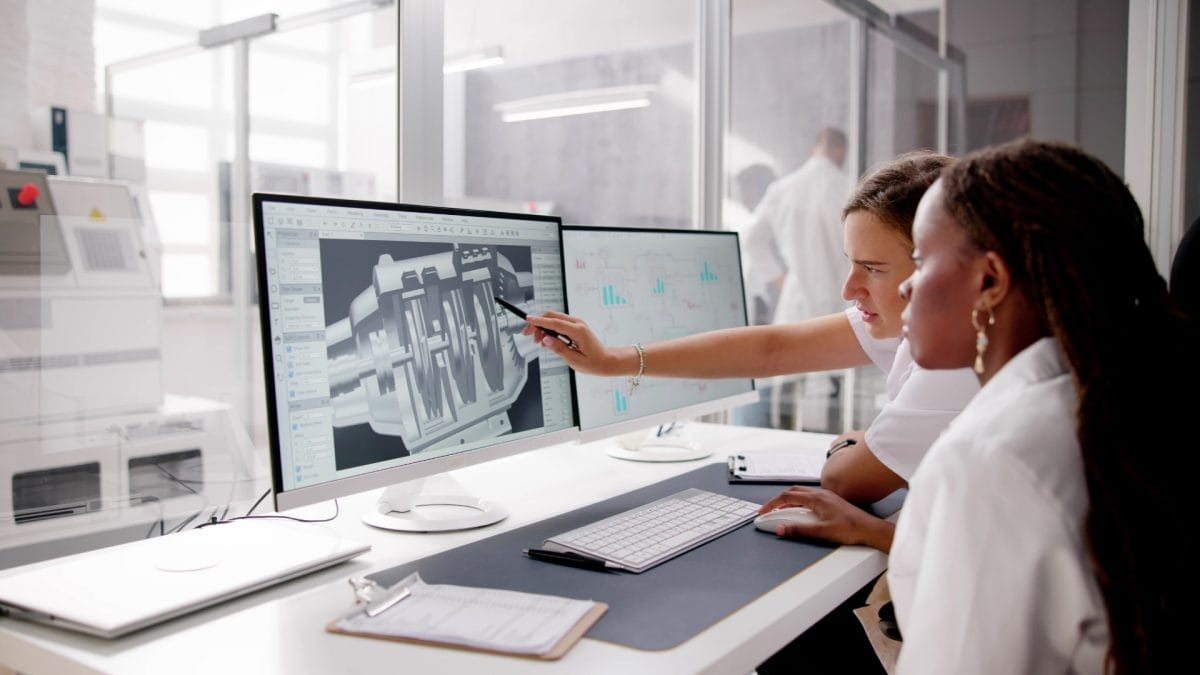

3D Modeling Process in Marine Interior Design

In the maritime industry, 3D ship interior design is crucial for the smooth progression of production and outfitting processes. 3D modeling is used to plan, visualize, and test interior furniture before production. The interior design processes of marine vessels—such as ships, yachts, and cruise ships—must meet aesthetic, functional, and safety criteria. In this context, 3D modeling is employed to design ship interiors and create marine furniture specifically tailored for marine vessels.

Why is 3D Modelling Important for Ship Interior Design?

3D visualisation studies for ship interiors provide a detailed preview of how the project will look before it begins. These design processes enable the early detection of potential errors in ship interiors, eliminating the need for costly revisions. Precise planning is especially important in ship designs with limited interior space, where every millimetre counts.

Advantages of 3D Modelling:

Realistic visualisations for approval stages

Precise space optimisation

Seamless collaboration between shipbuilders and designers

Accurate lighting, texture, and material simulation

Advanced simulation and visualisation tools

How Does the 3D Modelling Process Work?

The 3D modelling process we offer at CITA Marine Furniture consists of five key steps:

- Needs Analysis and Briefing Meeting

Before the project begins, a needs analysis (planning) is conducted. During this phase, the type of vessel, user group, targeted passenger experience, and specific requirements are discussed. Based on this analysis, the interior marine furniture needs are identified and aligned on a common ground.

- Concept Design Development

Initially, 2D layouts are created, and concept designs are developed. At this stage, colour palettes, material selections, and furniture layout plans take clear shape.

- 3D Modelling and Visualisation

Once the concept is approved, the 3D ship interior design modelling process begins. The proposed furniture layouts are transferred into a 3D environment. Materials, colours, and lighting are simulated to provide a highly realistic representation of the space. The project is presented to the client using advanced visualisation techniques.

- Customer Approval and Revisions

When the 3D model is complete, it is presented to the client in detail. Feedback is gathered, and necessary revisions are made. Once the final approval is received, the production phase begins.

The approved model is directly transferred to production without any changes. The production and installation of the custom marine furniture are completed under the assurance and expertise of CITA Marine Furniture.

What Are the Advantages of Working with CITA Marine Furniture?

Our company makes a professional contribution to the ship interior design process with work that complies with advanced European standards. In this context:

We work exclusively with experts in marine interior furniture design, supported by our experienced team.

We ensure compliance with IMO and MED certifications by providing high-quality products that meet European standards.

We deliver projects on time with full documentation support, ensuring fast and certified completion.

We combine aesthetics and functionality by blending user-friendly designs with elegant finishes.

With our 3D modelling process, you can clearly visualise your project before production, saving both time and cost.

If you are looking for perfectionist solutions for ship interiors, elevate your project with CITA Marine Furniture. Every project is special to us and reflects our commitment to high-quality service.

Perfection in interior spaces begins with detail and continues with design — and we masterfully craft those details through 3D modelling. Contact us today to discover our budget-friendly 3D design project prices!

Ship interior design company in London

Ship interior design company in Miami

Ship interior design company in Turkey